The choice of energy sources to power a feed dryer depends on various factors such as the availability of resources, local regulations, and economic considerations. Here are some common energy sources that can be used to power feed dryers, along with their respective costs and efficiencies:

Electricity:

Cost: The cost of electricity varies widely based on location and demand. It is typically measured in kilowatt-hours (kWh).

Efficiency: Electric feed dryers can be highly efficient in converting energy to heat. However, their overall efficiency may depend on the efficiency of the electricity generation in the specific region.

Natural Gas:

Cost: The cost of natural gas is usually measured in price per unit volume (e.g., dollars per cubic meter or dollars per therm).

Efficiency: Natural gas feed dryers are known for their high efficiency, as natural gas is a relatively clean and efficient fuel source for heat generation.

Propane:

Cost: Propane is often priced per gallon or per liter, and its cost can vary depending on the location and market conditions.

Efficiency: Propane-powered feed dryers are generally efficient and can provide a consistent source of heat.

Biomass:

Cost: The cost of biomass as an energy source depends on its availability, the local market, and the costs associated with processing and transporting the biomass material.

Efficiency: Biomass feed dryers can be efficient and environmentally friendly, especially if using waste biomass from agricultural or forestry activities.

Solar Thermal:

Cost: The cost of solar thermal systems involves the initial investment in solar collectors and related infrastructure.

Efficiency: Solar thermal feed dryers harness energy from the sun and can be efficient, particularly in sunny regions. However, their performance may vary based on weather conditions.

Waste Heat Recovery:

Cost: The cost of waste heat recovery systems depends on the scale and complexity of the installation.

Efficiency: This approach involves utilizing waste heat from other industrial processes to power the feed dryer, making it an energy-efficient option.

It's important to note that the costs and efficiencies of these energy sources can vary significantly based on geographical location, market conditions, technological advancements, and government incentives or subsidies. When choosing an energy source, it's essential to conduct a detailed cost-benefit analysis considering all relevant factors to determine the most suitable and economically viable option for powering the

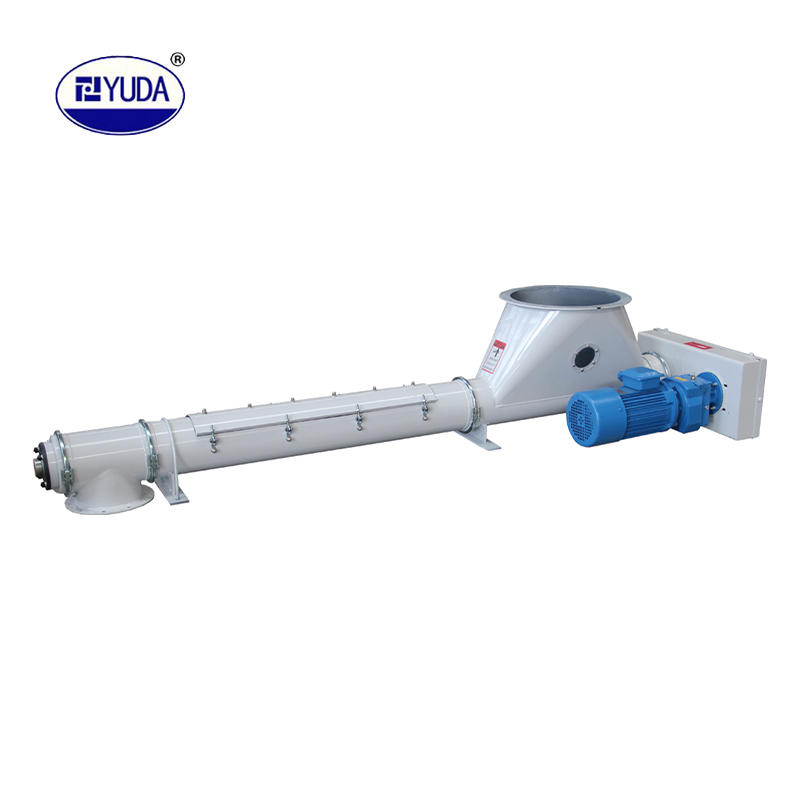

Feed Dryer Equipment in a specific context.

English

English Español

Español عربى

عربى Français

Français

Tel: 0086-519-87905108

Tel: 0086-519-87905108  Email:

Email: