● Fully controlled by computer, with few operating parameters, mainly need to type int the capacity and oil coating ratio, the system will run automatically, very convenient operation.

● After being placed in extruding and drying, it is suitable for spraying liquid such as oil, enzyme, vitamin, antioxidant and amino acid in large proportion on the surface of puffed feed. (Pelletized feed is not suitable for this product because of the small space inside the pellet and the small amount of liquid added.)

● Precise spraying ratio, large spraying volume, high uniformity of spraying.

● Good vacuum and negative pressure maintenance.

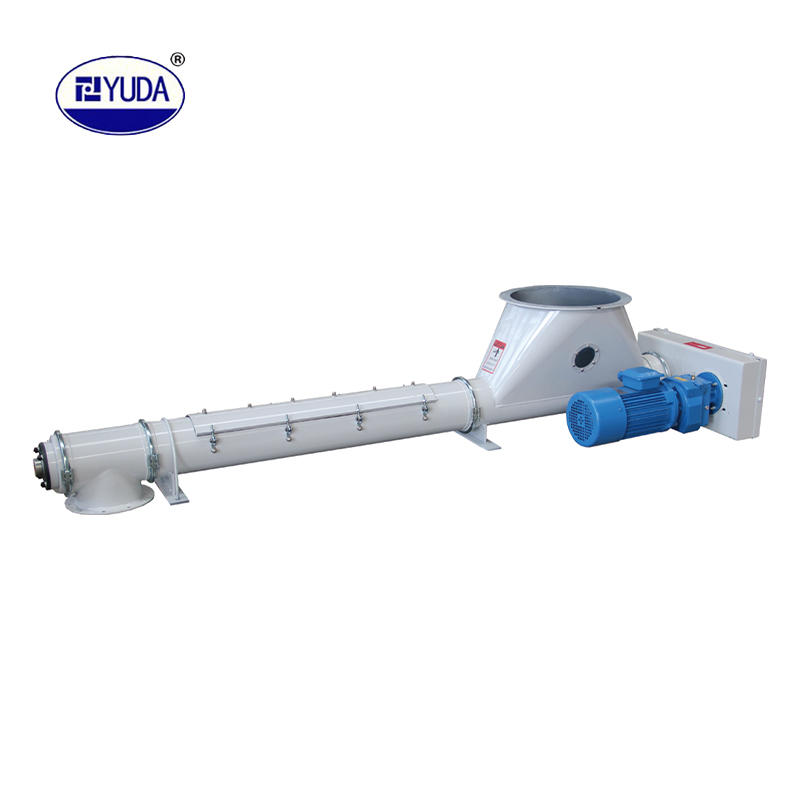

Description of Workflow

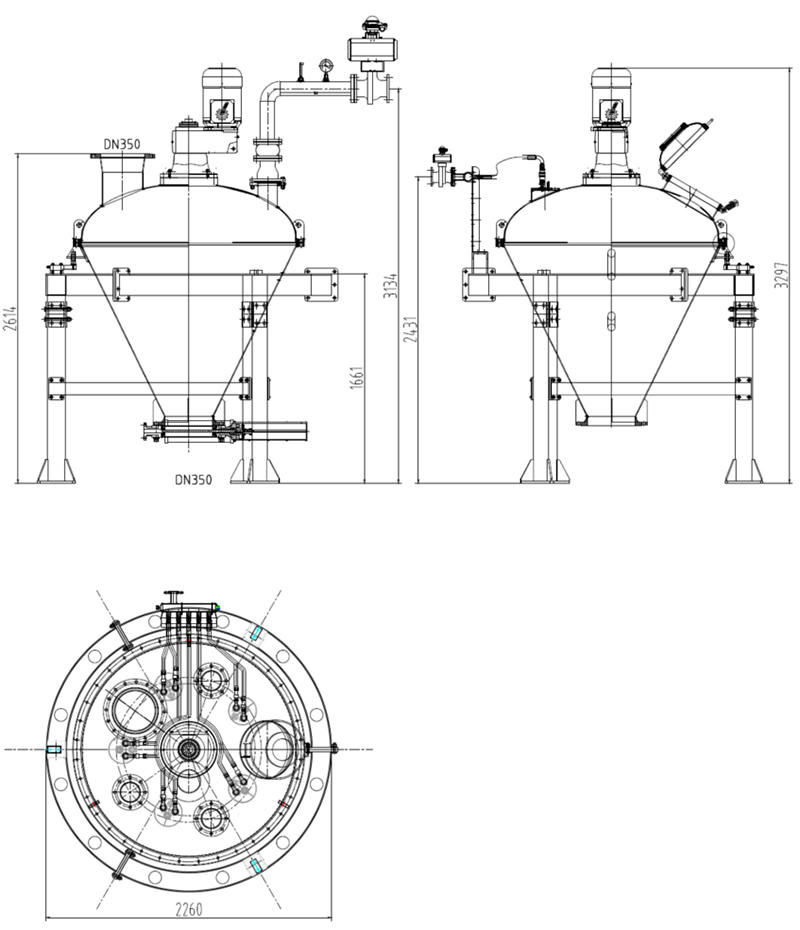

● The dosage scale in the upper part of the machine finishes weighing and the weighing value is detected by the computer ready to receive the command; the computer calculates the weight of the liquid and starts weighing it.

● The discharge gate is in the closed state. the inlet gate is opened, the weighing gate is opened, the material is counted into the injector, the feeding process spindle is rotating positively for about 15 seconds until the material is fed.

● Close the feeding gate, close the oil gate; the upper part of the batching scale into the next batch weighing.

● Vacuum valve opens, vacuum extraction starts, the required vacuum reaches the set value (-0.5--0.9 bar by operator input value), the vacuum pump and the pneumatic ball valve at 2 places close.

● The lifting screw starts rotating at low speed and then rapidly accelerates to the normal speed (inverter set value)

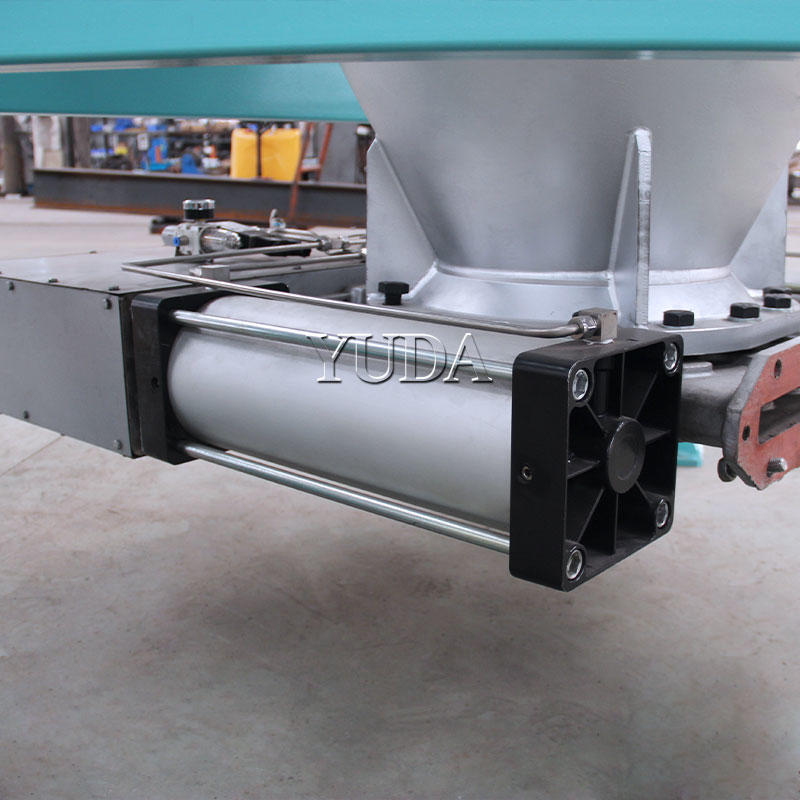

● Liquid pump starts to work, liquid valve opens and oil is injected. The liquid pressure is about 3 bar. When the added quantity is completed, the liquid valve and the liquid pump are closed and the frequency of the lifting screw is reduced to 2/3.

● Vacuum make-up air is opened, controlled by pneumatic valve, the first make-up air valve is opened first, then the second make-up air valve is opened after 15 seconds. The pressure returns to normal pressure when the air replenishment is completed.

● The bottom valve opens, the lifting spiral stops, when the weight reaches stability and no longer falls, the lifting spiral reverses 15 seconds (to ensure that the spiral is emptied of all materials).

● The metering computer shows that it has been emptied, and the bottom valve is closed. Complete a working cycle.

English

English Español

Español عربى

عربى Français

Français

Tel: 0086-519-87905108

Tel: 0086-519-87905108  Email:

Email: