Accurate mixing to improve product quality

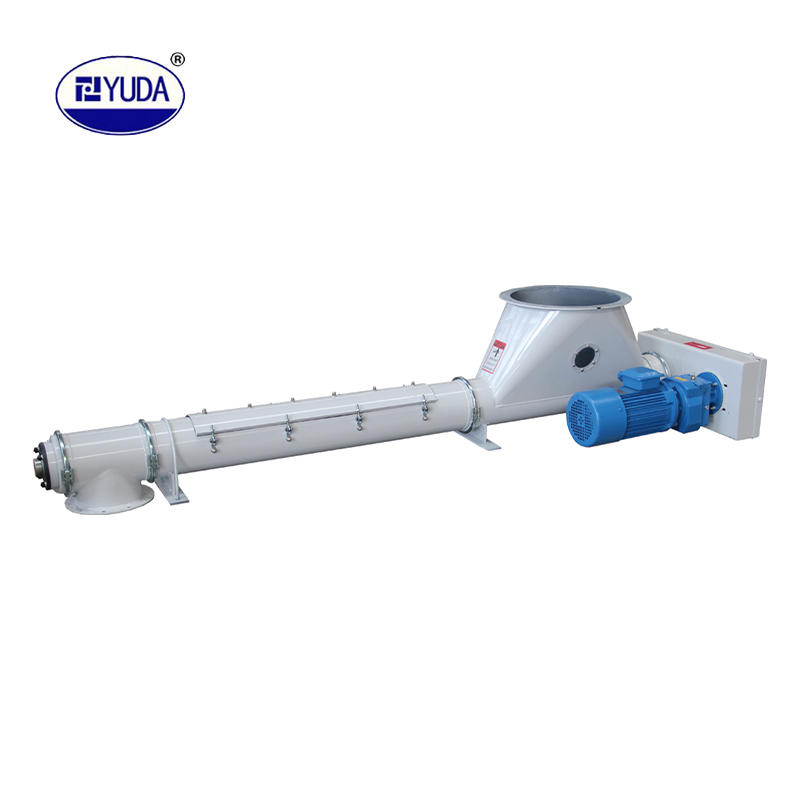

For feed production, the mixing uniformity of raw materials is a key factor in determining the quality of the final product. Through its innovative design, the horizontal feed mixer can achieve efficient mixing of different types of raw materials, ensuring that the ingredients of each batch of feed are completely consistent. Its unique structure ensures that the uniform distribution of powder, particles and liquid raw materials is completed in a short time, avoiding the uneven distribution of components that may occur in traditional mixing methods.

Since there are many types of raw materials involved in animal feed and the nutritional components and proportion requirements of each raw material are different, uniform mixing can not only ensure the quality of each feed pellet, but also ensure that the animals can intake all the nutrients they need, thereby improving the health and production efficiency of animals. This is particularly important for the sustainable development of the aquaculture industry.

Double improvement of efficiency and cost

Efficient production is the key to gaining competitive advantages in the feed industry. In large-scale production, the working efficiency of production equipment directly affects the length of production cycle and cost control. The horizontal feed mixer can complete uniform mixing work in a very short time, significantly shortening the production cycle. Due to its structural optimization, the operating efficiency of the machine has been greatly improved and the production speed has also been greatly increased, reducing the time and labor costs of the enterprise.

In addition, horizontal feed mixers reduce the generation of unqualified products and reduce waste of raw materials due to uneven mixing. This not only helps feed manufacturers improve production efficiency, but also indirectly reduces the procurement costs of materials and improves the overall benefits of the company.

Adapt to different production scales and needs

Whether it is a small-scale farm or a large feed production factory, horizontal feed mixers can provide flexible solutions based on actual production needs. Small farming companies usually have diversified demands and fast formula changes, while large factories pay more attention to the efficiency and stability of equipment. Horizontal feed mixers can be customized according to different production scales to meet various production needs and help enterprises achieve the perfect combination of personalized production and large-scale production.

As the market demand for functional, special formula feeds increases, more and more feed manufacturers need to deal with raw materials with complex formulas. At this time, the precise control and efficient mixing ability of horizontal feed mixers are particularly important. It can adapt to the mixing requirements of a variety of raw materials and complex formulas, ensuring stability and consistency in quality for each batch of products.

High durability and low maintenance costs

The durability and low maintenance costs of feed production equipment have always been a major concern in the industry. The horizontal feed mixer is designed to fully consider the needs of long-term high-strength operation, and adopts high-quality wear-resistant materials and advanced processing technology, which makes the equipment have a long service life. In addition, the maintenance of the equipment is relatively simple, and users can easily perform daily maintenance, thereby avoiding frequent shutdowns and high repair costs.

Environmental protection and energy saving

Against the backdrop of increasing environmental awareness, energy conservation and carbon emission reduction have become common goals for all industries. The horizontal feed mixer not only improves production efficiency, but also performs outstandingly in energy saving. By optimizing the drive system and stirring method, energy waste is reduced. Compared with traditional mixing equipment, its energy consumption is lower and meets the production requirements of green and environmentally friendly.

English

English Español

Español عربى

عربى Français

Français

Tel: 0086-519-87905108

Tel: 0086-519-87905108  Email: yudagrace@yudamachinery.com

Email: yudagrace@yudamachinery.com