- Home

- Product

- Silos

- Grain Pre-Cleaning Equipment

- Grinding Equipment

- Feed Mixing Equipment

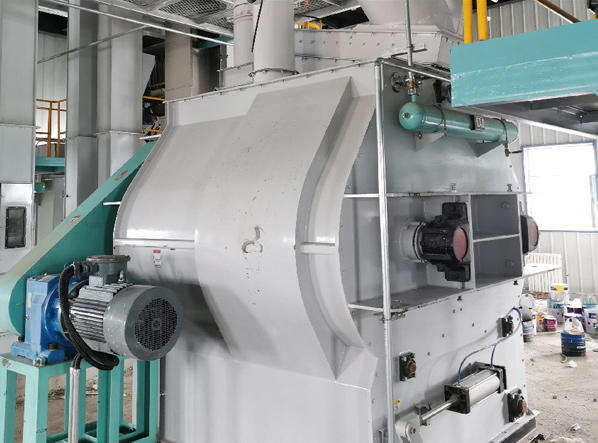

- Granulating Equipment

- Extruder Equipment

- Liquid Adding System And Vacuum Coater

- Feed Cooling Equipment

- Feed Dryer Equipment

- Feed Crumbling Equipment

- Sifting Equipment

- Conveying Equipment

- Automatic Packing Scale

- Auxiliary equipment

- Feed Machine's Spare Parts

- Solution

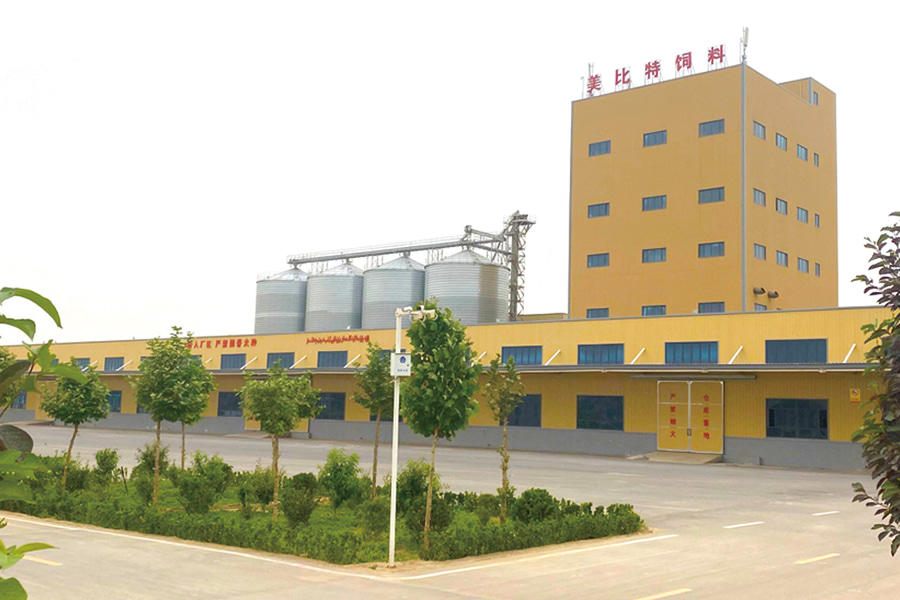

- Project & Case

- About

- Service

- News

- Contact Us

- Privacy

English

English Español

Español عربى

عربى Français

Français

Tel: 0086-519-87905108

Tel: 0086-519-87905108  Email:

Email: