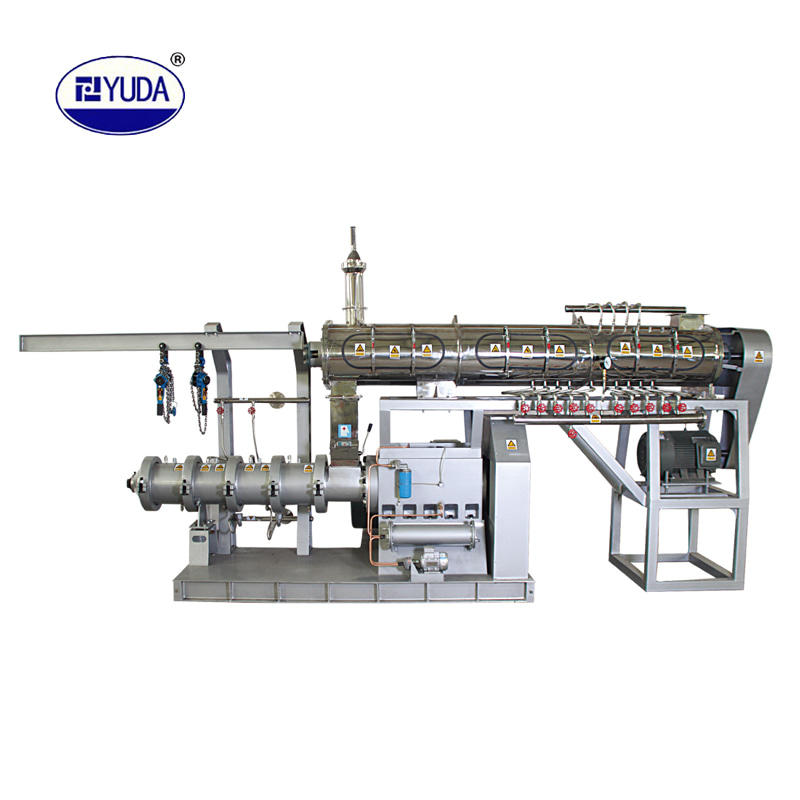

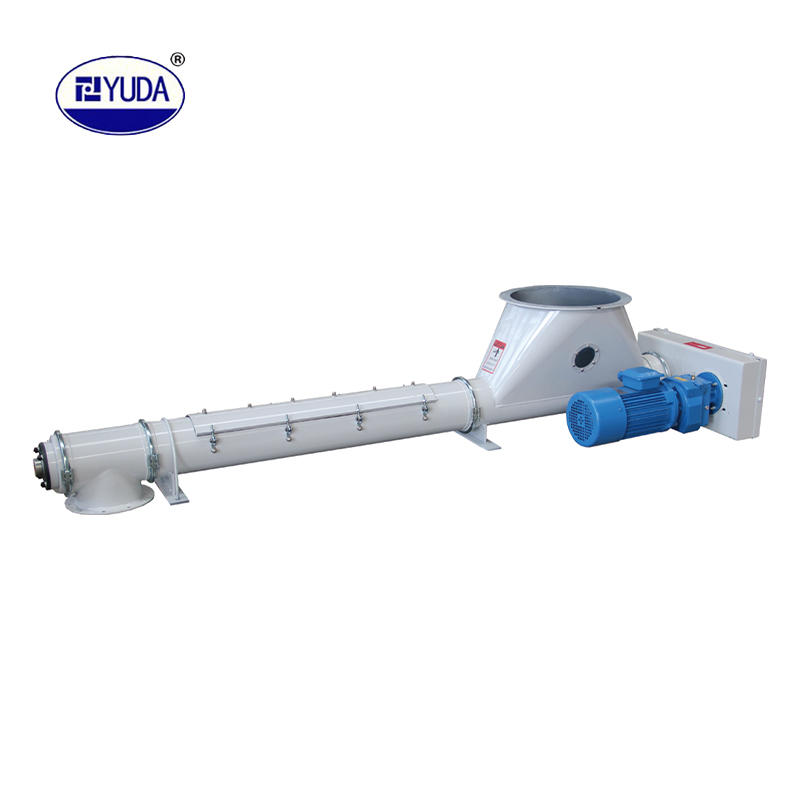

● New design enables the main shaft can stand much more thrust and torque than common type.

● Steam addition in conditioner can be controlled more accurately and conveniently,otherwise liquid can be well distributed.

● Special designed inlet ensures non block and backward.

● Fast discharge valve under conditioner can prevent stuff enter the barrel in an emergency.

● Enhanced adaptability.lt can process soybean,corn,compound feed continuously and smoothly with high performance.

● This kind of extruder can also be used as expander.Small changes in configuration make it easy to switch between extruder and expander for different purpose.

● It is particularly suitable for large and middle scale feedmills to extrude raw materials,expand feeds for poultry and livestock,form expanding-pelleting procedure.

English

English Español

Español عربى

عربى Français

Français

Tel: 0086-519-87905108

Tel: 0086-519-87905108  Email: yudagrace@yudamachinery.com

Email: yudagrace@yudamachinery.com