TGSU Series Drag Conveyor

● Small volume, high efficiency, low energy consumption;

● Simple structure, good tightness, convenient installation and repair;

● Chain adopts sleeve roller chain and head pulley and tail pulley adopt small pitch sprocket, resulting in smooth running;

● The housing is of U-shape and its bottom is of semi-circle. The shape of drag is also of semi-circle which matches the bottom. It is made of engineering plastics and has features of low noise, good guiding and no remainder.

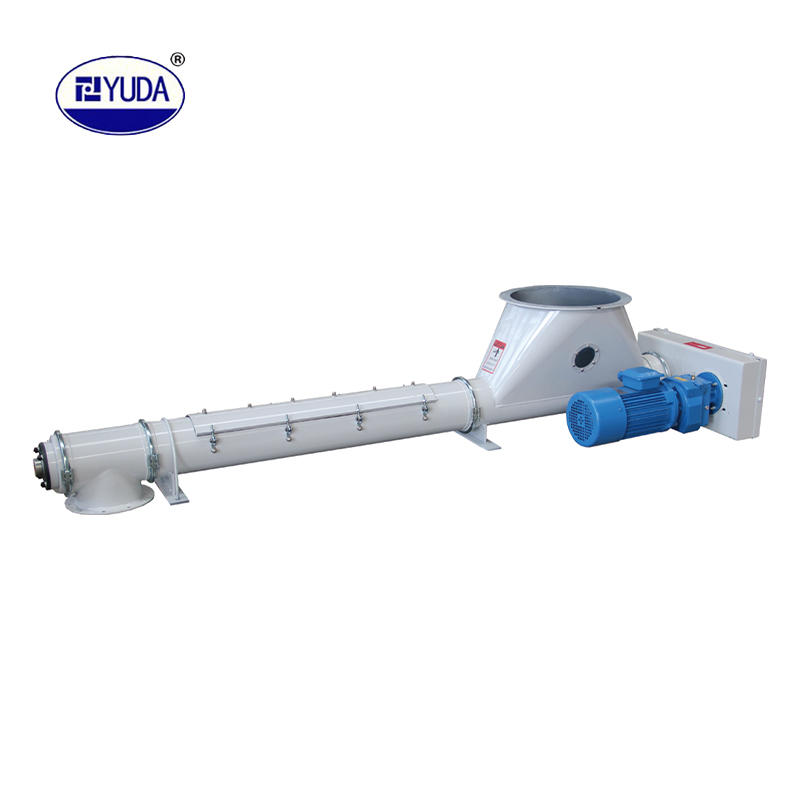

TGSS Series Buried Scraper Conveyor

This machine is of simple structure, small size, good seal performance, reasonable structure, guide rail USES plastic wear-resisting board, effectively reduce the noise and material breakage, prolongs the service life of the machine at the same time. Overload, the machine can start, has many characteristics, such as energy saving, easy operation and maintenance, the machine should not be transporting materials in bulk density is greater than 1 t/M3, and high temperature, high humidity, corrosive materials, bulk material.

English

English Español

Español عربى

عربى Français

Français

Tel: 0086-519-87905108

Tel: 0086-519-87905108  Email: yudagrace@yudamachinery.com

Email: yudagrace@yudamachinery.com