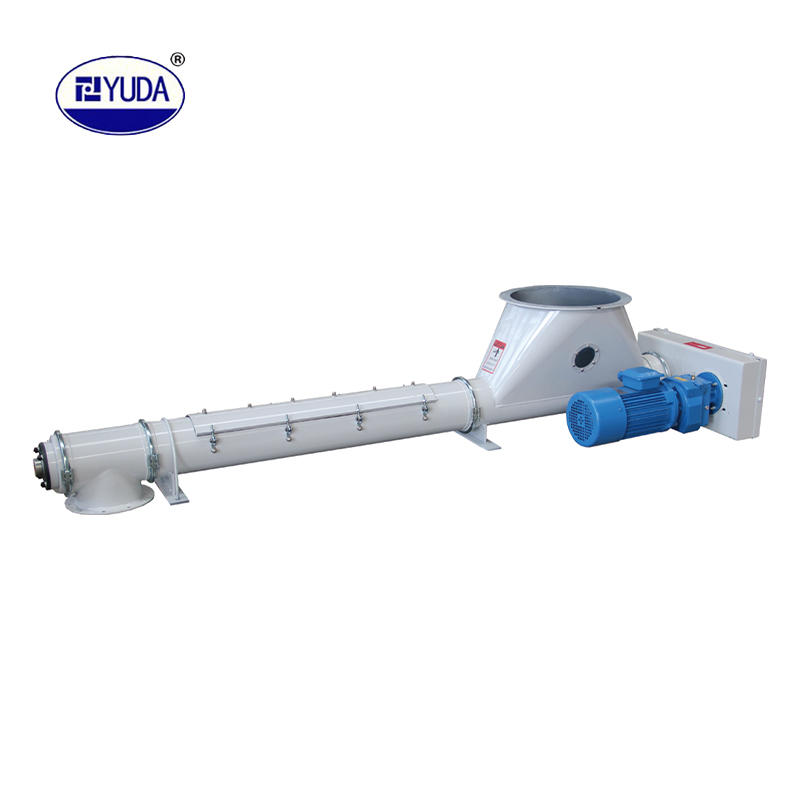

● High capacity, low energy consumption, smooth and reliable running, compact structure, small space occupation.

● Horizontal cantilever sifting cylinder is used. The sifting cylinder is divided into feeding section and discharging section. Different mesh combination is adopted separately and corresponding capacity and separating efficiency can be obtained.

● Cleaning is realized through inside sifting and outside brushing. In the sifting process, fibre impurities and grain straw are discharged by guide screw conveyor in the shape of ball. Cleaning can be carried out reliably.

● Contrary feeding is adopted. The discharging section of sifting cylinder is fitted with screw conveyor, which increases the actual sifting length so as to reach sufficient sifting and avoid the containing of clean materials in the impurities.

● Convenient repairing, simple installation and convenient replacement of sifting cylinder.

English

English Español

Español عربى

عربى Français

Français

Tel: 0086-519-87905108

Tel: 0086-519-87905108  Email: yudagrace@yudamachinery.com

Email: yudagrace@yudamachinery.com