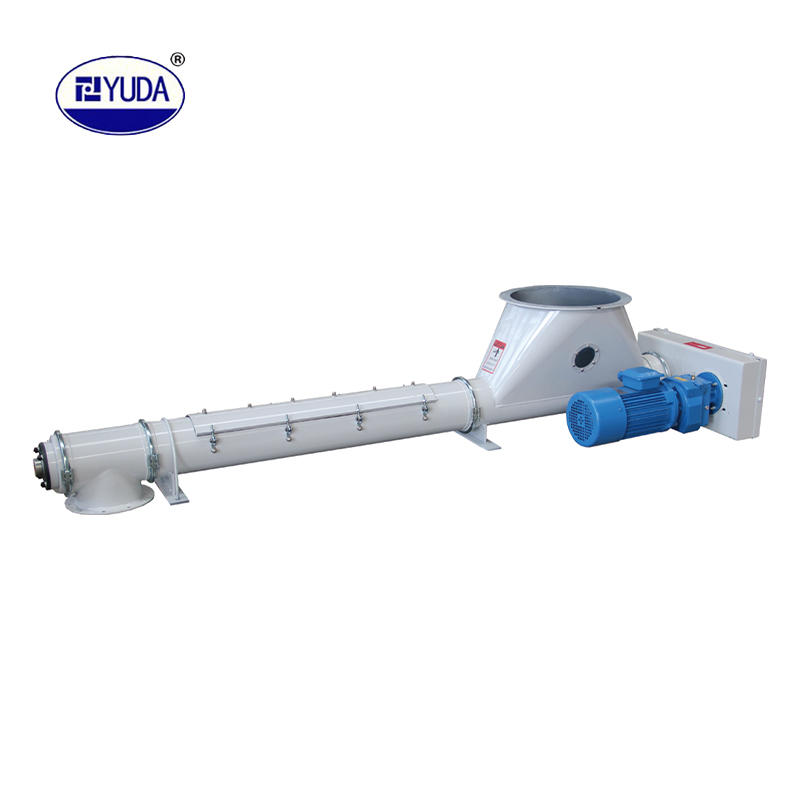

★Adopting advanced submerged machine control processing technology, three trash discharging controls, improve speed, keep clearness; hanging liver type weighing structure, further improve accuracy.

★This product consists of material control device, clamping device, weighing control system and package, fine feeding machine.

★The parts in contact with materials are made of 304 stainless steel tungsten, with high corrosion resistance.

★Central belt device is suitable for male woven bags, hemp city, he lai, cloth bags and plastic bags, etc.

English

English Español

Español عربى

عربى Français

Français

Tel: 0086-519-87905108

Tel: 0086-519-87905108  Email: yudagrace@yudamachinery.com

Email: yudagrace@yudamachinery.com