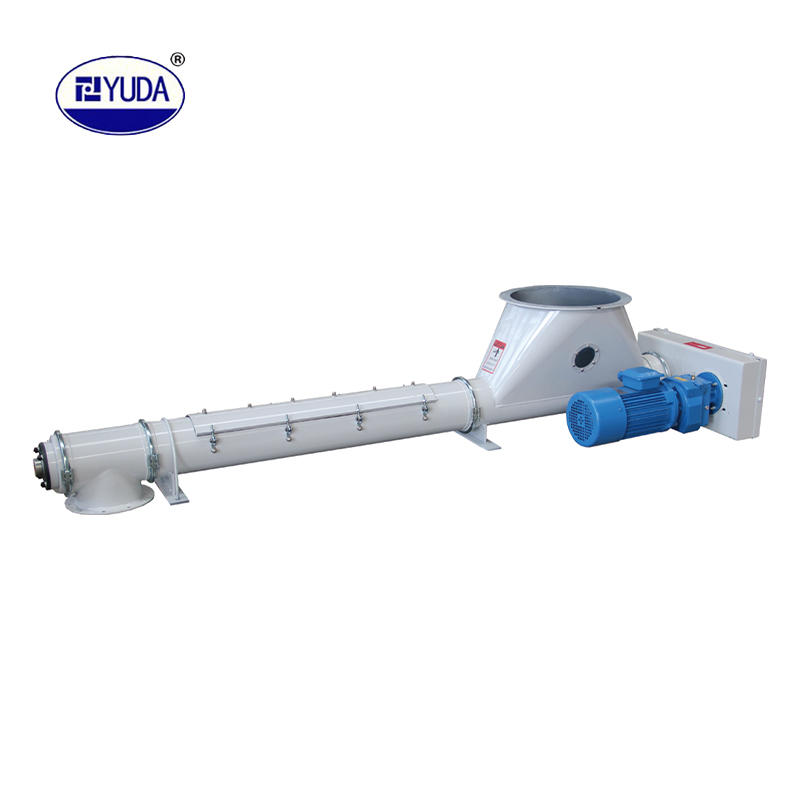

Liyang Yuda Machinery Co.,Ltd is China SLHY Series Feed Ribbon Mixer Manufacturers and SLHY Series Feed Ribbon Mixer Company . The company has introduced a complete set of world-class technology CNC laser cutting machines, automatic profile sandblasting equipment, automatic welding machines, large-scale shearing and bending equipment, CNC lathes, etc. Undertake various types and scales of complete turnkey projects for feed, including complete plant planning, design, equipment manufacturing, installation and commissioning, and personnel training.

Technology and quality are the life of YUDA; the company adheres to the business philosophy of "honesty and quality", strict quality control, relying on strong scientific research, "integrity, pragmatism, pioneering and innovative". "Intelligent" manufacturing is in a leading position in the domestic and foreign industries.

English

English Español

Español عربى

عربى Français

Français

Tel: 0086-519-87905108

Tel: 0086-519-87905108  Email: yudagrace@yudamachinery.com

Email: yudagrace@yudamachinery.com